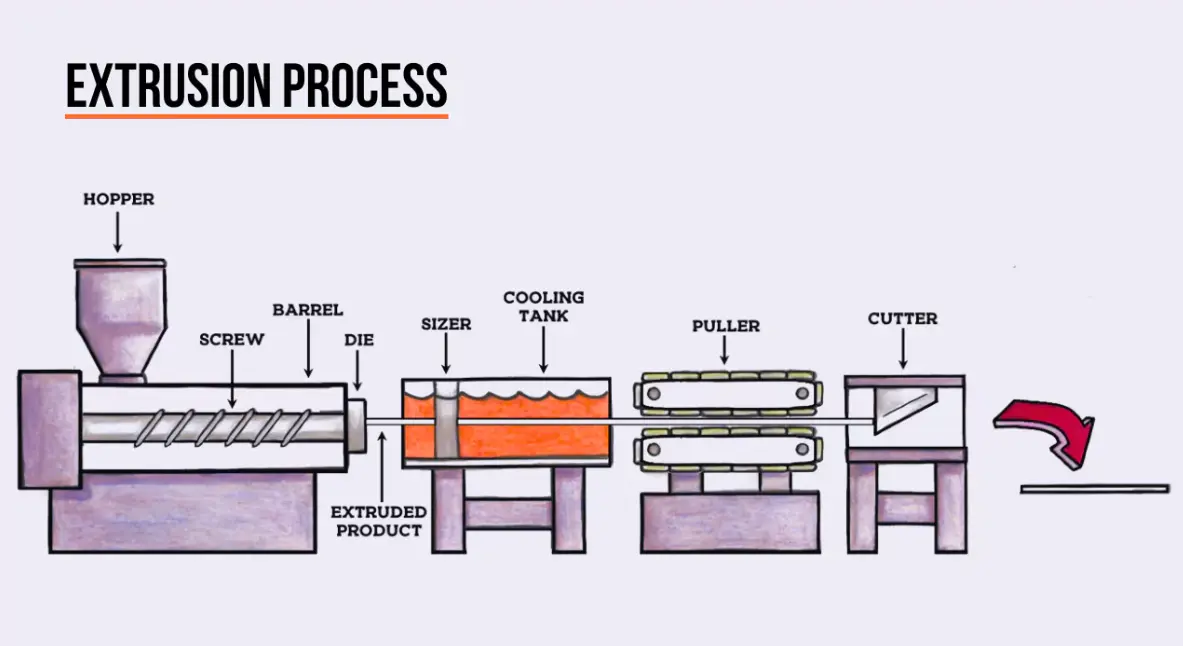

Extrusion is a versatile manufacturing process that involves forcing a material, such as metal, plastic, or rubber, through a shaped die to create objects with a consistent cross-sectional profile. This method is widely used to produce long, uniform items like pipes, tubes, rods, and profiles, offering efficiency in mass production due to its ability to handle various materials and achieve precise shapes with minimal waste. By applying heat and pressure, the material is softened and extruded, allowing for customization in industries such as construction, automotive, and packaging.

Table of Contents

- Part 1: OnlineExamMaker – Generate and Share Extrusion Quiz with AI Automatically

- Part 2: 20 Extrusion Quiz Questions & Answers

- Part 3: Save Time and Energy: Generate Quiz Questions with AI Technology

Part 1: OnlineExamMaker – Generate and Share Extrusion Quiz with AI Automatically

OnlineExamMaker is a powerful AI-powered assessment platform to create auto-grading Extrusion skills assessments. It’s designed for educators, trainers, businesses, and anyone looking to generate engaging quizzes without spending hours crafting questions manually. The AI Question Generator feature allows you to input a topic or specific details, and it generates a variety of question types automatically.

Top features for assessment organizers:

● Prevent cheating by randomizing questions or changing the order of questions, so learners don’t get the same set of questions each time.

● AI Exam Grader for efficiently grading quizzes and assignments, offering inline comments, automatic scoring, and “fudge points” for manual adjustments.

● Embed quizzes on websites, blogs, or share via email, social media (Facebook, Twitter), or direct links.

● Handles large-scale testing (thousands of exams/semester) without internet dependency, backed by cloud infrastructure.

Automatically generate questions using AI

Part 2: 20 Extrusion Quiz Questions & Answers

or

1. Question: What is the primary principle of the extrusion process?

Options:

A. Casting molten material into a mold

B. Forcing material through a die to create a specific shape

C. Cutting material with a rotating tool

D. Joining two materials by heat and pressure

Answer: B

Explanation: Extrusion involves pushing or drawing material through a die, which shapes it into a continuous profile with a fixed cross-section.

2. Question: Which type of extrusion is commonly used for metals like aluminum?

Options:

A. Cold extrusion

B. Hot extrusion

C. Blow extrusion

D. Injection extrusion

Answer: B

Explanation: Hot extrusion is used for metals to reduce the material’s strength and increase ductility by heating it above its recrystallization temperature.

3. Question: What is the main advantage of extrusion over other shaping processes?

Options:

A. It produces complex internal shapes

B. It allows for continuous production of uniform cross-sections

C. It requires minimal equipment

D. It is ideal for small-scale manufacturing

Answer: B

Explanation: Extrusion enables the efficient, continuous production of long lengths of material with consistent cross-sections, making it cost-effective for high-volume applications.

4. Question: In extrusion, what role does the die play?

Options:

A. It heats the material

B. It shapes the material as it passes through

C. It cools the extruded product

D. It stores the raw material

Answer: B

Explanation: The die determines the final shape and size of the extruded product by restricting the flow of material into the desired profile.

5. Question: Which material is most commonly extruded in the plastics industry?

Options:

A. Steel

B. Polyethylene

C. Wood

D. Glass

Answer: B

Explanation: Polyethylene is widely used in extrusion due to its versatility, low melting point, and ability to form various profiles like pipes and films.

6. Question: What defect might occur if extrusion speed is too high?

Options:

A. Surface roughness

B. Warping or distortion

C. Perfect uniformity

D. Increased strength

Answer: B

Explanation: High extrusion speeds can cause uneven cooling and material flow, leading to warping or distortion in the final product.

7. Question: In which industry is extrusion frequently used for food processing?

Options:

A. Automotive

B. Aerospace

C. Food and beverage

D. Textile

Answer: C

Explanation: Extrusion is used in food processing to create products like pasta and cereals by forcing dough through dies under heat and pressure.

8. Question: What is the purpose of the preheating stage in extrusion?

Options:

A. To cool the material

B. To soften the material for easier flow

C. To harden the die

D. To add color to the product

Answer: B

Explanation: Preheating reduces the viscosity of the material, making it easier to push through the die and ensuring uniform extrusion.

9. Question: Which extrusion method involves blowing air into the material?

Options:

A. Direct extrusion

B. Blow extrusion

C. Indirect extrusion

D. Hydrostatic extrusion

Answer: B

Explanation: Blow extrusion, often used for plastics, involves inflating the material with air to form hollow shapes like bottles.

10. Question: How does cold extrusion differ from hot extrusion?

Options:

A. It uses higher temperatures

B. It is performed at or near room temperature

C. It produces weaker products

D. It requires more energy

Answer: B

Explanation: Cold extrusion is done at room temperature, which maintains the material’s strength and surface finish without the need for heating.

11. Question: What parameter is critical for controlling the quality of extruded products?

Options:

A. Extrusion temperature

B. Room lighting

C. Operator’s age

D. Die color

Answer: A

Explanation: Extrusion temperature affects material flow, viscosity, and final properties, making it essential for achieving consistent quality.

12. Question: In extrusion, what is the function of the screw in a single-screw extruder?

Options:

A. To cut the material

B. To mix and convey the material through the barrel

C. To cool the die

D. To store excess material

Answer: B

Explanation: The screw rotates to melt, mix, and push the material forward through the extruder barrel toward the die.

13. Question: Which factor can lead to uneven thickness in extruded profiles?

Options:

A. Consistent die design

B. Variations in material feed rate

C. Low pressure

D. Excessive cooling

Answer: B

Explanation: Inconsistent material feed rates can cause fluctuations in the extrusion process, resulting in uneven thickness.

14. Question: What is hydrostatic extrusion?

Options:

A. Extrusion using water pressure

B. Extrusion in a vacuum

C. Standard hot extrusion

D. Extrusion with air blowing

Answer: A

Explanation: Hydrostatic extrusion uses fluid pressure to surround and extrude the material, allowing for uniform pressure distribution and complex shapes.

15. Question: Why is lubrication important in metal extrusion?

Options:

A. To add color to the product

B. To reduce friction and wear on the die

C. To increase material hardness

D. To speed up cooling

Answer: B

Explanation: Lubrication minimizes friction between the material and the die, preventing damage and ensuring smooth extrusion.

16. Question: In polymer extrusion, what does the term “draw ratio” refer to?

Options:

A. The speed of the extruder

B. The ratio of the die cross-section to the final product cross-section

C. The temperature difference

D. The material’s density

Answer: B

Explanation: Draw ratio measures how much the extruded material is stretched, affecting its orientation, strength, and final dimensions.

17. Question: What is a common application of extrusion in the construction industry?

Options:

A. Manufacturing car parts

B. Producing PVC pipes

C. Creating electronic circuits

D. Designing clothing

Answer: B

Explanation: Extrusion is ideal for creating long, uniform PVC pipes used in plumbing and construction due to its efficiency and cost-effectiveness.

18. Question: How does indirect extrusion work?

Options:

A. The ram moves through the die

B. The die moves into the material

C. Material is pulled instead of pushed

D. Heat is not required

Answer: B

Explanation: In indirect extrusion, the die is forced into the stationary billet, allowing for better control and reduced friction compared to direct methods.

19. Question: What might cause bubbles or voids in extruded plastic products?

Options:

A. Proper material mixing

B. Trapped air or moisture in the material

C. High extrusion pressure

D. Slow cooling rates

Answer: B

Explanation: Trapped air or moisture can expand during extrusion, leading to bubbles or voids in the final plastic product.

20. Question: Which extrusion process is used for creating seamless tubes?

Options:

A. Profile extrusion

B. Tube extrusion

C. Film extrusion

D. Wire coating extrusion

Answer: B

Explanation: Tube extrusion specifically forms hollow tubes by extruding material around a mandrel, ensuring a seamless and uniform structure.

or

Part 3: Save Time and Energy: Generate Quiz Questions with AI Technology

Automatically generate questions using AI