Machine safety is a critical aspect of workplace safety, especially in industrial settings where machines and equipment are used regularly. Ensuring machine safety is essential to prevent accidents, injuries, and even fatalities. Machine-related hazards can arise from moving parts, electrical components, sharp edges, and other potential dangers. Employers, workers, and machine operators must adhere to safety guidelines and implement safety measures to protect everyone in the vicinity of machines. Here’s an overview of key machine safety principles:

Machine Guarding: Install appropriate machine guards, barriers, and shields to prevent access to hazardous areas, such as moving parts or dangerous zones.

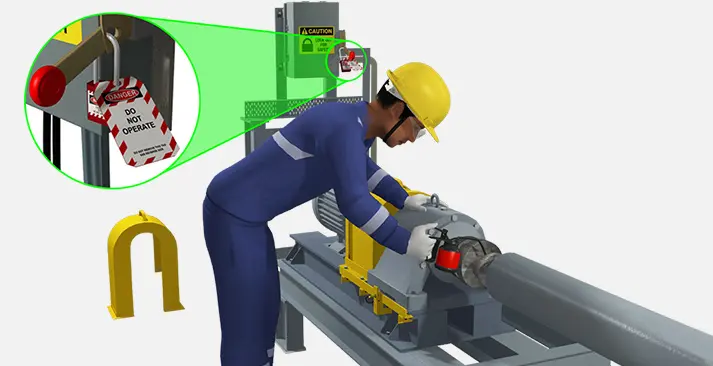

Lockout/Tagout (LOTO): Implement a comprehensive LOTO procedure to ensure machines are safely shut down and isolated from energy sources during maintenance and repair.

Operator Training: Provide comprehensive training to machine operators to understand the machine’s operation, potential hazards, and safety protocols.

Personal Protective Equipment (PPE): Mandate the use of appropriate PPE, such as safety goggles, gloves, and ear protection, to minimize the risk of injuries from machine operations.

Regular Inspections: Conduct routine inspections and maintenance of machines to identify and rectify any potential safety issues promptly.

Emergency Stop Devices: Equip machines with easily accessible emergency stop buttons or switches to quickly shut down operations in case of emergencies.

Pro Tip

Want to assess your learners online? Create an online quiz for free!

In this article

- Part 1: OnlineExamMaker AI quiz generator – The easiest way to make quizzes online

- Part 2: 30 machine safety quiz questions & answers

- Part 3: Download machine safety questions & answers for free

Part 1: OnlineExamMaker AI quiz generator – The easiest way to make quizzes online

When it comes to ease of creating a machine safety skills assessment, OnlineExamMaker is one of the best AI-powered quiz making software for your institutions or businesses. With its AI Question Generator, just upload a document or input keywords about your assessment topic, you can generate high-quality quiz questions on any topic, difficulty level, and format.

What you will like:

● AI Question Generator to help you save time in creating quiz questions automatically.

● Share your online exam with audiences on social platforms like Facebook, Twitter, Reddit and more.

● Display the feedback for correct or incorrect answers instantly after a question is answered.

● Create a lead generation form to collect an exam taker’s information, such as email, mobile phone, work title, company profile and so on.

Automatically generate questions using AI

Part 2: 30 machine safety quiz questions & answers

1. What is the primary purpose of machine guarding?

a) Enhancing the appearance of the machine

b) Preventing unauthorized access to the machine

c) Protecting workers from hazardous machine parts

d) Making the machine more efficient

Answer: c) Protecting workers from hazardous machine parts

2. What is Lockout/Tagout (LOTO) used for?

a) Identifying the owner of the machine

b) Preventing the machine from being used by unauthorized personnel

c) Ensuring proper machine maintenance and repair

d) Keeping machines running smoothly

Answer: c) Ensuring proper machine maintenance and repair

3. Which of the following is NOT considered personal protective equipment (PPE)?

a) Safety goggles

b) Ear protection

c) Machine guards

d) Safety gloves

Answer: c) Machine guards

4. Why is it essential for machine operators to receive proper training?

a) To learn how to operate the machine faster

b) To improve communication skills with co-workers

c) To understand potential hazards and safety protocols

d) To know the history of the machine

Answer: c) To understand potential hazards and safety protocols

5. What is the purpose of conducting routine inspections on machines?

a) To identify malfunctioning machines for repair

b) To increase productivity and efficiency

c) To evaluate workers’ performance

d) To check the quality of machine parts

Answer: a) To identify malfunctioning machines for repair

6. What should be done if an emergency stop is activated on a machine?

a) Continue using the machine with caution

b) Reset the machine and resume normal operations

c) Investigate the cause of the emergency stop and address the issue

d) Ignore the emergency stop and continue working

Answer: c) Investigate the cause of the emergency stop and address the issue

7. What safety measure should be taken when working with electrical components of machines?

a) Use bare hands for better grip

b) Stand on a wet surface to avoid static electricity

c) Ground the machine and use appropriate personal protective equipment (PPE)

d) Connect machines to unstable power sources

Answer: c) Ground the machine and use appropriate personal protective equipment (PPE)

8. When is it appropriate to wear personal protective equipment (PPE)?

a) Only when the supervisor is present

b) Only when using heavy machinery

c) At all times while working with machines

d) Never, as PPE restricts movement

Answer: c) At all times while working with machines

9. What should you do before using a machine for the first time?

a) Start operating the machine immediately

b) Ask your co-workers for help and guidance

c) Read the instruction manual and receive proper training

d) Modify the machine to suit your preferences

Answer: c) Read the instruction manual and receive proper training

10. Why should machines have visible hazard signage?

a) To warn unauthorized personnel to stay away from the machines

b) To enhance the appearance of the machine

c) To attract more attention to the machine

d) To make the workplace more colorful

Answer: a) To warn unauthorized personnel to stay away from the machines

11. What is one of the benefits of implementing a lockout/tagout (LOTO) procedure?

a) Reducing machine efficiency

b) Ensuring proper machine maintenance

c) Improving communication between workers

d) Increasing machine speed

Answer: b) Ensuring proper machine maintenance

12. Which type of personal protective equipment (PPE) should be used to protect the eyes from debris and flying particles?

a) Ear protection

b) Safety goggles

c) Safety gloves

d) Hard hat

Answer: b) Safety goggles

13. Why is it important to conduct regular safety training for machine operators?

a) To give them a break from their regular duties

b) To improve their productivity

c) To ensure they understand machine hazards and safety procedures

d) To test their knowledge of the machines

Answer: c) To ensure they understand machine hazards and safety procedures

14. What is the purpose of an emergency stop button on a machine?

a) To turn off the machine at the end of the workday

b) To stop the machine immediately in case of an emergency

c) To change the machine’s settings quickly

d) To turn on additional machine features

Answer: b) To stop the machine immediately in case of an emergency

15. How can workers protect themselves from potential electrical hazards while using machines?

a) Use the machines with wet hands

b) Avoid wearing personal protective equipment (PPE)

c) Ground the machines and use appropriate PPE

d) Disconnect the machines from power sources during use

Answer: c) Ground the machines and use appropriate PPE

Part 3: Download machine safety questions & answers for free

Download questions & answers for free

16. Why is it important for machine operators to receive proper training?

a) To impress their supervisors

b) To understand potential hazards and safe operation of the machine

c) To become experts in operating the machine

d) To reduce the need for supervision

Answer: b) To understand potential hazards and safe operation of the machine

17. What is the primary purpose of conducting routine inspections on machines?

a) To check if the machines are being used efficiently

b) To identify potential hazards and malfunctions in the machines

c) To evaluate workers’ performance

d) To determine if the machines need new paint or decals

Answer: b) To identify potential hazards and malfunctions in the machines

18. What should be done in case of an emergency stop on a machine?

a) Reset the machine and continue working

b) Investigate the cause of the emergency stop and address the issue

c) Ignore the emergency stop and continue working

d) Use the machine more cautiously

Answer: b) Investigate the cause of the emergency stop and address the issue

19. How should you handle electrical components when working with machines?

a) Use bare hands for better grip

b) Stand on a wet surface to avoid static electricity

c) Wear personal protective equipment (PPE) and ground the machine

d) Avoid grounding the machine to prevent electrical hazards

Answer: c) Wear personal protective equipment (PPE) and ground the machine

20. When is it appropriate to wear personal protective equipment (PPE) while working with machines?

a) Only when using heavy machinery

b) Only when the supervisor is present

c) At all times while working with machines

d) Never, as PPE restricts movement

Answer: c) At all times while working with machines

21. What should you do before operating a machine for the first time?

a) Start using the machine and figure it out as you go

b) Ask your co-workers for help and guidance

c) Read the instruction manual and receive proper training

d) Modify the machine to suit your preferences

Answer: c) Read the instruction manual and receive proper training

22. What is one of the benefits of implementing a lockout/tagout (LOTO) procedure?

a) Improving communication between workers

b) Ensuring proper machine maintenance

c) Reducing machine efficiency

d) Increasing machine speed

Answer: b) Ensuring proper machine maintenance

23. Which type of personal protective equipment (PPE) should be used to protect the eyes from debris and flying particles?

a) Ear protection

b) Safety goggles

c) Safety gloves

d) Hard hat

Answer: b) Safety goggles

24. Why is it important to conduct regular safety training for machine operators?

a) To improve their productivity

b) To give them a break from their regular duties

c) To test their knowledge of the machines

d) To ensure they understand machine hazards and safety procedures

Answer: d) To ensure they understand machine hazards and safety procedures

25. What is the purpose of an emergency stop button on a machine?

a) To change the machine’s settings quickly

b) To turn on additional machine features

c) To turn off the machine at the end of the workday

d) To stop the machine immediately in case of an emergency

Answer: d) To stop the machine immediately in case of an emergency

26. How can workers protect themselves from potential electrical hazards while using machines?

a) Use the machines with wet hands

b) Avoid wearing personal protective equipment (PPE)

c) Ground the machines and use appropriate PPE

d) Disconnect the machines from power sources during use

Answer: c) Ground the machines and use appropriate PPE

Just so you know

With OnlineExamMaker quiz software, anyone can create & share professional online assessments easily.

27. Why is it important for machine operators to receive proper training?

a) To become experts in operating the machine

b) To impress their supervisors

c) To reduce the need for supervision

d) To understand potential hazards and safe operation of the machine

Answer: d) To understand potential hazards and safe operation of the machine

28. What is the primary purpose of conducting routine inspections on machines?

a) To check if the machines need new paint or decals

b) To evaluate workers’ performance

c) To identify potential hazards and malfunctions in the machines

d) To check if the machines are being used efficiently

Answer: c) To identify potential hazards and malfunctions in the machines

29. What should be done in case of an emergency stop on a machine?

a) Use the machine more cautiously

b) Reset the machine and continue working

c) Investigate the cause of the emergency stop and address the issue

d) Ignore the emergency stop and continue working

Answer: c) Investigate the cause of the emergency stop and address the issue

30. How should you handle electrical components when working with machines?

a) Use bare hands for better grip

b) Avoid grounding the machine to prevent electrical hazards

c) Wear personal protective equipment (PPE) and ground the machine

d) Stand on a wet surface to avoid static electricity

Answer: c) Wear personal protective equipment (PPE) and ground the machine