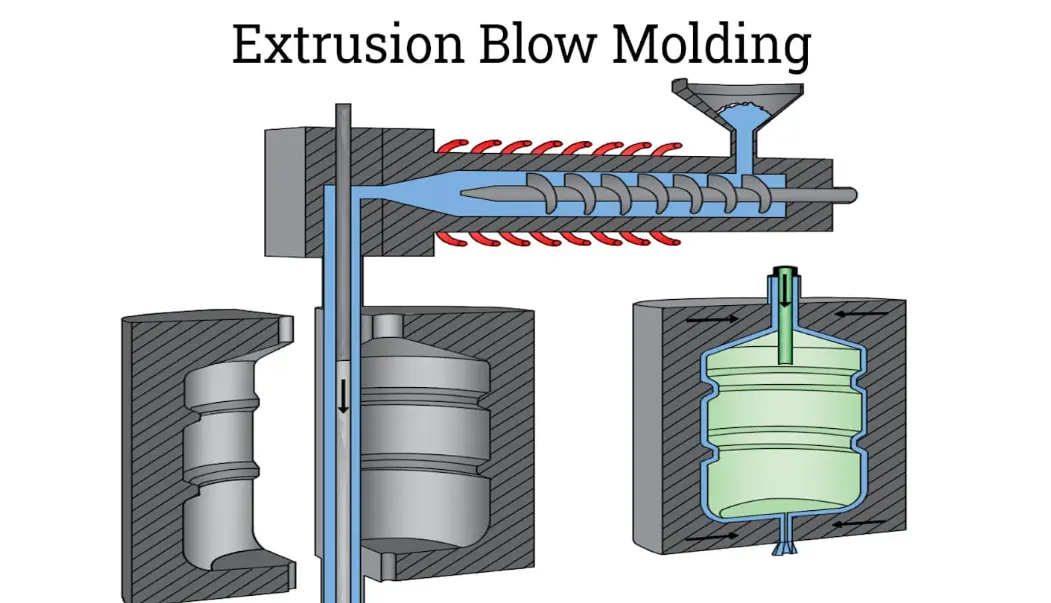

Blow molding is a versatile manufacturing process used to create hollow plastic products, such as bottles, containers, and automotive components. In this method, a heated plastic tube called a parison is placed into a mold and inflated with compressed air, causing it to expand and take the shape of the mold cavity. The process typically involves three main steps: extrusion or injection of the parison, closing the mold around it, and blowing air to form the final shape. Known for its efficiency, cost-effectiveness, and ability to produce lightweight, seamless items, blow molding is widely applied in industries like packaging, where it enables mass production of durable, high-quality goods. Variations include extrusion blow molding, injection blow molding, and stretch blow molding, each tailored to specific product requirements.

Table of Contents

- Part 1: Create An Amazing Blow Molding Quiz Using AI Instantly in OnlineExamMaker

- Part 2: 20 Blow Molding Quiz Questions & Answers

- Part 3: Save Time and Energy: Generate Quiz Questions with AI Technology

Part 1: Create An Amazing Blow Molding Quiz Using AI Instantly in OnlineExamMaker

Nowadays more and more people create Blow Molding quizzes using AI technologies, OnlineExamMaker a powerful AI-based quiz making tool that can save you time and efforts. The software makes it simple to design and launch interactive quizzes, assessments, and surveys. With the Question Editor, you can create multiple-choice, open-ended, matching, sequencing and many other types of questions for your tests, exams and inventories. You are allowed to enhance quizzes with multimedia elements like images, audio, and video to make them more interactive and visually appealing.

Recommended features for you:

● Prevent cheating by randomizing questions or changing the order of questions, so learners don’t get the same set of questions each time.

● Automatically generates detailed reports—individual scores, question report, and group performance.

● Simply copy a few lines of codes, and add them to a web page, you can present your online quiz in your website, blog, or landing page.

● Offers question analysis to evaluate question performance and reliability, helping instructors optimize their training plan.

Automatically generate questions using AI

Part 2: 20 Blow Molding Quiz Questions & Answers

or

Question 1:

What is the primary material used in blow molding?

A. Thermosetting plastics

B. Thermoplastics

C. Metals

D. Ceramics

Answer: B

Explanation: Thermoplastics are used because they can be heated, shaped, and cooled repeatedly without undergoing chemical change, making them ideal for the blow molding process.

Question 2:

In extrusion blow molding, what is the first step?

A. Injecting molten plastic into a mold

B. Blowing air into the parison

C. Extruding a tube of molten plastic

D. Cooling the final product

Answer: C

Explanation: The process begins with extruding a hollow tube of molten plastic, known as a parison, which is then placed in a mold for blowing.

Question 3:

What type of blow molding is commonly used for producing bottles?

A. Injection blow molding

B. Rotational molding

C. Compression molding

D. Thermoforming

Answer: A

Explanation: Injection blow molding is preferred for bottles as it allows for precise neck finishes and high production rates of hollow objects.

Question 4:

Which factor primarily affects the wall thickness in blow molding?

A. Mold temperature

B. Parison thickness and extrusion speed

C. Cooling time

D. Air pressure

Answer: B

Explanation: The parison’s thickness and the speed of extrusion determine how the material distributes in the mold, directly influencing the final wall thickness.

Question 5:

What is a key advantage of blow molding over injection molding?

A. Higher cost for tooling

B. Ability to produce complex shapes easily

C. Limited to small parts

D. Unsuitable for hollow objects

Answer: B

Explanation: Blow molding excels at creating hollow, complex shapes like containers with minimal additional processing, unlike injection molding which is better for solid parts.

Question 6:

In injection stretch blow molding, what additional step is involved?

A. Stretching the parison axially

B. Only heating the plastic

C. Rotating the mold

D. Compressing the material

Answer: A

Explanation: This process includes stretching the heated parison both axially and radially to improve material strength and clarity, often used for PET bottles.

Question 7:

What gas is typically used to inflate the parison in blow molding?

A. Nitrogen

B. Oxygen

C. Compressed air

D. Carbon dioxide

Answer: C

Explanation: Compressed air is used because it is readily available, cost-effective, and provides the necessary pressure to expand the parison against the mold walls.

Question 8:

Which defect in blow molding results from uneven cooling?

A. Warpage

B. Flash

C. Sink marks

D. Blisters

Answer: A

Explanation: Uneven cooling causes the plastic to shrink inconsistently, leading to warpage where the part distorts from its intended shape.

Question 9:

What is the role of the mold in blow molding?

A. To heat the plastic

B. To shape the final product

C. To extrude the parison

D. To recycle scrap material

Answer: B

Explanation: The mold defines the external shape of the product by containing the parison and allowing it to expand against its surfaces.

Question 10:

Which thermoplastic is most commonly used for blow-molded bottles?

A. Polypropylene (PP)

B. Polyethylene terephthalate (PET)

C. Polyvinyl chloride (PVC)

D. Polystyrene (PS)

Answer: B

Explanation: PET is favored for bottles due to its excellent barrier properties, clarity, and recyclability in blow molding applications.

Question 11:

How does blow molding differ from rotational molding?

A. Blow molding uses air pressure

B. Rotational molding creates hollow parts

C. Both are identical processes

D. Blow molding requires no mold

Answer: A

Explanation: Blow molding uses internal air pressure to form the shape, whereas rotational molding relies on heat and rotation to coat the mold interior.

Question 12:

What is the typical cycle time for blow molding a plastic bottle?

A. Several hours

B. 1-2 minutes

C. Less than 10 seconds

D. Over 30 minutes

Answer: B

Explanation: The cycle time is generally 1-2 minutes per part, allowing for efficient mass production in blow molding operations.

Question 13:

In blow molding, what causes “parison sag”?

A. Excessive cooling

B. Gravity pulling on the molten plastic

C. High air pressure

D. Mold misalignment

Answer: B

Explanation: Parison sag occurs when the weight of the molten plastic causes it to stretch downward due to gravity before blowing, affecting uniformity.

Question 14:

Which application is NOT typically associated with blow molding?

A. Fuel tanks

B. Toys

C. Solid gears

D. Containers

Answer: C

Explanation: Blow molding is designed for hollow parts like fuel tanks, toys, and containers, but not for solid items like gears, which require other processes.

Question 15:

What is the purpose of the pinch-off in blow molding?

A. To seal the bottom of the part

B. To add color to the plastic

C. To heat the mold

D. To remove excess material

Answer: A

Explanation: The pinch-off area in the mold seals the bottom of the hollow part, ensuring it forms a closed shape during the blowing process.

Question 16:

How does increasing air pressure affect blow molding?

A. It slows down production

B. It can cause thinner walls and potential defects

C. It has no effect

D. It thickens the walls

Answer: B

Explanation: Higher air pressure expands the parison more quickly, potentially leading to thinner walls or defects like blowouts if not controlled properly.

Question 17:

What type of blow molding is used for high-clarity products like cosmetic bottles?

A. Extrusion blow molding

B. Injection blow molding

C. Rotational blow molding

D. Compression blow molding

Answer: B

Explanation: Injection blow molding produces parts with superior surface finish and clarity, making it suitable for cosmetic and pharmaceutical bottles.

Question 18:

Why is blow molding energy-efficient for large-scale production?

A. It requires minimal heating

B. It uses less material for hollow parts

C. It needs constant manual intervention

D. It produces waste-free products

Answer: B

Explanation: Blow molding efficiently uses material by creating hollow structures, reducing weight and material costs compared to solid molding methods.

Question 19:

In blow molding, what is a parison?

A. The final molded product

B. A tube of molten plastic

C. The mold itself

D. Compressed air source

Answer: B

Explanation: A parison is the initial hollow tube of molten plastic that is inflated in the mold to form the desired shape.

Question 20:

What environmental benefit does blow molding offer?

A. It uses non-recyclable materials

B. It allows for easy recycling of thermoplastics

C. It increases waste production

D. It requires toxic additives

Answer: B

Explanation: Blow molding primarily uses recyclable thermoplastics, enabling products like bottles to be reused or recycled, reducing environmental impact.

or

Part 3: Save Time and Energy: Generate Quiz Questions with AI Technology

Automatically generate questions using AI